Let there be LIGHT! Hanbury Evans Light!

To students, student room lighting often comes across as horrible. Many dorm rooms still have overhead fluorescents that look bad and make rooms feel antiseptic. It’s no wonder that many dorm rooms end up adorned with all kinds of student-added lighting, from strings of Christmas lights to ping pong ball lights and, according to posts on Pinterest, “fairy lights.”

School administrators have their own beefs with student room lighting. It’s expensive. While LED lighting costs have dropped in recent years, student room lighting is still a noticeable portion of construction budgets and therefore an obvious target for value engineering.

For every single or double room, an LED fixture will often run $500. That fixture may get downgraded as everyone works to keep construction on budget. Then, rooms end up with cheaper fixtures that deliver poor light, use more electricity and wear out quickly, running up maintenance costs.

“Most universities have tight budgets and don’t believe they can move into LED technology,” says Jesse Jernigan, co-owner of Resource Lighting. Based in Virginia, it contracts with manufacturers to sell lighting products.

As designers of campus space, we know that universities and colleges struggle to control costs but still want to provide students and faculty with quality spaces built with sustainable products.

While working with one of our clients, the University of Tennessee, we set to work on something we’d long wanted to do: Design an attractive LED dorm room light that was high quality and affordable.

The result? The Hanbury Evans light, which costs about $300 and delivers 4,700 lumens of light. That is about 60 percent more than traditional overhead lights. The light can be dimmed and has a good color rendering index. Colors in the room, say red or orange, are very true.

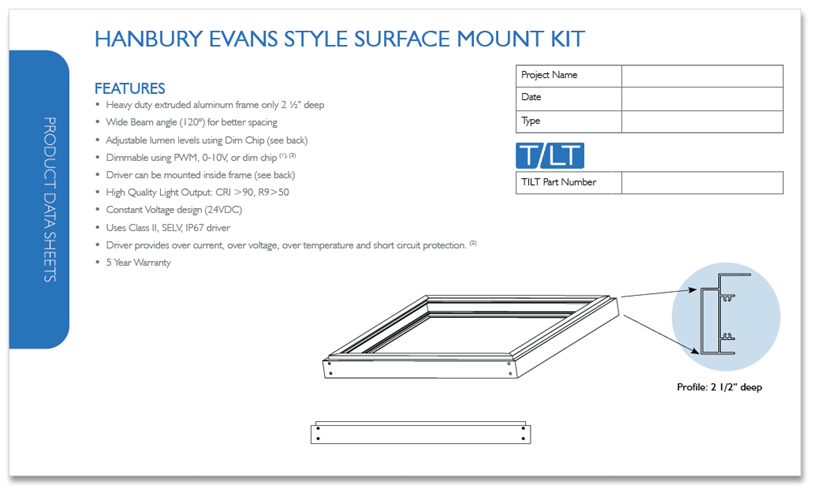

The key to the light is a two-foot by two-foot, one-half-inch thick LED light panel from manufacturer Lauren Illumination. The panel is normally recessed inside a ceiling. In this case, the light engine goes inside an extruded aluminum frame, which Hanbury designed. The frame is flush mount to the ceiling.

The University of Tennessee is expected to use the light in approximately 1,500 student rooms. Wake Forest University is using it in new freshman housing and another housing renovation project. We expect to use the light in most of our housing projects because of its cost, appearance and performance.

We hope the light hastens the adoption of LED technology in higher education. LED adoption is now “moving rapidly” in the university setting, Jernigan says. Almost 45 percent of its higher education orders are LED, up from about 25 percent two years ago. Because of reduced energy consumption and lowered maintenance costs, many universities and colleges are seeing payback for the higher upfront investment in as little as two years, Jernigan says. The Hanbury Evans light is rated to last 50,000 hours. If the light was on for eight hours a day, 300 days of the year, that would be about 20 years.

More colleges and universities are also opting for LED lights because they don’t contain mercury, as do fluorescents, and can be recycled, says Chuck Laney, president of Lauren Illumination. Lights that contain mercury have special disposal requirements.

That an architecture firm designed a light might sound off task. It isn't. As we design buildings, we often create specialized lighting fixtures to give spaces just the right look and feel. We hope this light spreads into ever more student rooms—although we doubt it’ll fully replace the Christmas light strings.